You do not need a crystal ball or a fortune teller to see the customer demand for the months to come – we have a much more precise approach for you. With demand forecasting, you can use historical data and past sales data to get much more than a glimpse of future demand and prepare your business for what’s to come. Here’s how to do that.

In this article, you’ll find:

- The demand forecasting definition.

- Battle-tested demand forecasting methods, models and techniques, both qualitative and quantitative.

- The factors that might affect demand forecasting in your business.

- The best demand forecasting tools that can make the whole process much simpler.

What Is Demand Forecasting? Definition

Demand forecasting estimates consumer demand for a product or service based on historical data, market trends, and other influencing factors. As such, it helps businesses anticipate what, how much, and when customers are likely to buy, and, consequently, helps managers prepare for the upcoming challenges and opportunities.

Why Is Demand Forecasting Important?

But why should you bother with this process in the first place?

Demand forecasting helps businesses make smarter decisions about production, staffing, inventory, and finances both in long- and short-term perspective, helping them manage everyday challenges. By predicting future demand, companies can avoid overstocking or stockouts, reduce waste, and allocate resources more efficiently. This leads to better budgeting, improved cash flow, and streamlined operations.

It also enhances customer satisfaction and gives companies a competitive edge. With accurate forecasts, businesses can respond quickly to market changes, meet customer expectations consistently, and reduce the risk of unexpected disruptions. In short, demand forecasting turns uncertainty into strategic advantage.

Demand Forecasting Methods

Ultimately, demand forecasting has one goal: to determine what projects your business will be working on, when, with which resources, and for how much. While the final outcome of the process might remain the same, there are different demand forecasting techniques that will lead you to that goal.

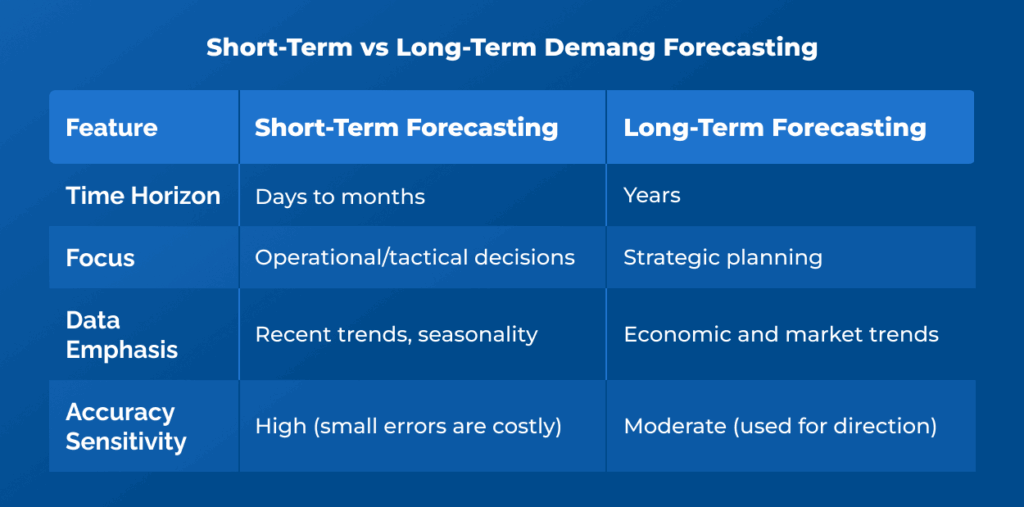

Short-Term Demand Forecasting

Short-term demand forecasting is a perfect choice for companies aiming to predict demand in the short run, preferably 3 to 6 months. Typically, this method is used daily, weekly or monthly to make quick, tactical decisions for resource and workload management, such as adjusting schedules, replenishing inventory, managing supply chain or reassigning specialists to projects.

Long-Term Demand Forecasting

Companies looking for a bit more strategical approach to the next 1 to 3 years should definitely be more interested in long-term demand forecasting methods. This technique was designed to support and organize key processes, such as capacity management, product development, and capital investments. It is also a valuable tool for sales departments, which can use it to draw conclusions from historical sales data and improve their pipeline for the months to come.

Active Demand Forecasting

Looking for a more dynamic approach? Active demand forecasting is definitely one of them. These demand forecasting methods aim to see the future demand by factoring in planned business activities and external influences, such as economic trends and competitive landscape, rather than relying solely on past sales data. For example, a fashion retailer launching a spring collection might use active demand forecasting by blending:

- Past spring season industry trends

- Current social media buzz

- Planned influencer partnerships

- Weather forecasts

The result? A more responsive and forward-looking forecast that takes risk management to a whole new level.

Passive Demand Forecasting

Does your company specializes in collecting historical data? Then passive demand forecasting is definitely a method tailored to your needs. It assumes that past patterns, such as trends, seasonality, and customer behavior, will continue into the future without significant change, helping companies in stable industries plan their future demand.

While this demand forecasting technique is relatively easy to implement, it leaves no room for unexpected factors and might lead to large discrepancies between prognosis and actual demand.

Quantitative Demand Forecasting Models

In today’s competitive landscape, using data-driven insights to make decisions is a backbone of scalable business strategies. Quantitative demand forecasting methods are a direct consequence of such approach, as they use numerical data and mathematical techniques to predict future demand. They are especially useful when you have sufficient historical data and want objective, data-driven forecasts.

Main quantitative methods for forecasting demand include:

Time Series Models

One of the simplest methods of demand forecasting, time series models rely purely on historical patterns (trends, seasonality, cycles) to determine the future demand in the organization. Still, as this method does not take any external factors into consideration, they require additional processes to remain accurate. Those typically include:

- Moving average, or forecasts based on the average of a fixed number of past periods.

- Expotential smoothing that weighs recent observations more heavily than older ones and adds trends and seasonality to the equation.

- ARIMA (AutoRegressive Integrated Moving Average), which combines autoregression, differencing, and moving average components to forecast demand in non-seasonal industries.

- SARIMA (Seasonal ARIMA), or a ARIMA technique accounting for seasonal changes.

Regression Analysis

But how to consider more factors in your demand forecasting? Regression analysis is the answer to this question. This technique is used to estimate the relationship between demand (the dependent variable) and one or more independent variables (like price, advertising spend, seasonality, income levels, etc.) by putting a line (or curve) through data points to model how changes in input variables affect demand. As a result, it produces more accurate forecasts than methods relying exclusively on historical data.

Machine Learning Models

Still, large organizations managing multiple variables at the same time would struggle fitting all the data into simple demand forecasting models. That’s where state-of-the-art demand forecasting solution comes into play, offering them machine learning techniques as a support for this process.

Machine learning (ML) models for demand forecasting use algorithms to learn patterns from historical data and make predictions about future demand. These models are especially useful when dealing with large datasets, complex relationships, or non-linear trends that traditional statistical methods may not capture effectively.

Qualitative Demand Forecasting Models

Sometimes proper demand forecasting requires more than just solid data. Expert knowledge, experience and industry-specific insights sometimes play a huge part in accurate demand forecasting – and that’s what qualitative demand forecasting use to be successful. Here are the most common of them.

Expert Opinion Method (Delphi Method)

Have numerous experts in your team? It’s time to use their knowledge to forecast customer demand for the months to come.

In Expert Opinion Method (often referred to as Delphi Method), forecasts are created by a panel of experts who participate in multiple rounds of questioning. Their responses are anonymized, summarized, and shared after each round, allowing participants to revise their answers. The process continues until a consensus is reached, minimizing bias, eliminating the worst scenarios and choosing the best course of action for the upcoming processes.

Market Research (Customer Expectations)

Market environment is one of the most critical factors in making business decisions. This demand forecasting technique acknowledges its importance by turning industry data into accurate predictions. This involves collecting primary data through surveys, interviews, or focus groups to understand consumer preferences, purchase intentions, and emerging trends. It is especially useful for forecasting demand for new products or entering unfamiliar markets.

Sales Force Composite

If the sales pipeline is crucial for the success of your company, putting it at the core of your forecasts might be a perfect solution. In this method, sales representatives provide forecasts based on their knowledge of customers, territories, and current market conditions. These individual estimates are then aggregated to form a company-wide forecast. Still, due to a more narrower approach, this method might lack some valuable insights from other departments, which might need to add their opinions to final predictions.

What Factors Influence Accuracy of Demand Forecasting?

The reliability of a demand forecast depends on a range of internal and external variables. Those include:

Quantity and Availability of Data

The accuracy of your forecast is only as good as the data behind it. Incomplete, outdated, or inconsistent data can lead to flawed projections. More reliable models should use different types of data, from resources to costs, to provide managers with a complete overview of key processes regardless of the market circumstances.

Market Volatility

Sudden shifts in the market, such as economic downturns, supply chain disruptions, or competitive actions, can make past trends less predictive. Such unexpected events are a perfect reason to revisit previous assumptions and alter them to the new reality created by sudden shifts in your industry.

Seasonality

In many industries, fluctuations tied to seasons, holidays, or cyclical events can significantly affect demand. Forecasts are more accurate when historical patterns around recurring periods are factored in and adjusted accordingly.

Forecasting Systems

Endless spreadsheets are not your best friend when it comes to demand forecasting. Outdated or overly simplistic forecasting tools can limit your ability to process data and generate useful insights. Using modern forecasting systems that integrate machine learning, automation, and real-time data inputs – such as BigTime – can significantly improve forecast accuracy, especially in fast-moving environments.

Consumer Preferences

Customer behavior and preferences can shift quickly for dozens of reasons ranging from new trends to changing values. If your forecasting doesn’t account for these evolving preferences, you risk basing decisions on outdated assumptions.

How to Choose The Right Demand Forecasting Methods?

So many choices, so little time… So which demand forecasting methods should you really use?

In reality, both qualitative and quantitative assessments have their pros and cons. As a result, using just one demand forecasting model is not enough. To get a bird’s eye view of all the future endeavours, it’s best to use multiple techniques covering different factors influencing the final outcomes. By doing so, managers can test both positive and negative scenarious without missing any opportunities.

Demand Forecasting Process Step by Step

Every project manager needs to know who does what, and when. Still, figuring that out a few weeks or months into the future is not an easy task. Fortunately, a proven demand forecasting process can turn general assumptions into precise plans in just a few steps. Here’s what they look like.

1. Define The Objective.

Before you jump straight to advanced analytics and demand trends, you need to identify the purpose of your demand forecasting. What’s its use? What fields should it cover – only projects, or maybe also resources, financial planning, and more? How are you going to use the conclusions your demand forecasters will arrive at?

Then, after establishing the basics, you can try to identify the general specifics of your forecast. Is it going to be a long- or a short-term one? What factors will it include? Choose the data that your company is particularly interested in to avoid excessive work later in the process.

2. Collect Necessary Data.

Historical data, past sales data, information from market research – those are just a few types of insights uou will need for accurate demand forecasting. At this stage of demand forecasting, focus on collecting as many pieces of information as possible to get a bigger picture of all the operations – and all the possibilities. To make data collection even more accurate, remember to clean the data and add any information on seasonal demand or external factors that can later impact your business performance.

3. Choose Forecasting Models and Metrics.

Once you have the data, select the forecasting method that best fits your business needs. Will you use qualitative models based on expert opinions, or quantitative models such as time series analysis or regression? Define the metrics you’ll use to measure forecast accuracy—such as Mean Absolute Percentage Error (MAPE) or Root Mean Square Error (RMSE)—so you can evaluate and fine-tune your forecast over time.

4. Analyze The Data and Make Decisions

Use the selected forecasting model to analyze your data and generate predictions. Look for patterns, correlations, and outliers that could impact future demand. Based on the results, make informed decisions about project timelines, staffing needs, procurement, or budgeting. At this point, collaboration across departments with real time data is critical to validate assumptions and align on next steps.

5. Monitor and Refine.

While demand forecasts can give managers an idea of what’s to come in the next weeks and months, they are rarely 100% accurate. To ensure that your plans will reflect the current state of your projects, regularly revisit your schedules and compare them to the actual demand to prevent scope crawl, delays, and, untimately, ensure project success regardless of the circumstances.

What Factors Hinder Effective Demand Forecasting?

Even the most well-designed forecasting process can fall short if certain barriers get in the way. From inconsistent data to sudden market shifts, many factors can reduce the accuracy and reliability of your forecasts. Here are some of the most common ones to watch out for:

- Poor data quality. Incomplete, outdated, or inaccurate data can throw off even the most advanced forecasting models. Always ensure that your inputs are trustworthy before relying on the outputs.

- Lack of historical data. Forecasting models, especially quantitative ones, depend heavily on past trends. But if you’re launching a new product, entering a new market, or undergoing significant business changes, historical data may be limited or irrelevant. In these cases, consider using qualitative methods or analogies to similar past scenarios.

- Ignoring external factors. Your company is not alone in the universe. Factors such as seasonality, economic conditions, competitor actions, or even weather can significantly influence outcomes. Leaving them out means missing critical context.

- Rapid market changes. In fast-moving industries, trends shift quickly and unpredictably. A forecast that was accurate three months ago may now be outdated. The more volatile your environment, the shorter your forecasting window should be.

- Lack of updates. A forecast is not a one-and-done task. If you don’t revisit and adjust your projections as new data and events unfold, you risk relying on outdated assumptions.

Want to Forecast Demand In Seconds? Use BigTime!

For many project managers, active demand forecasting equals long hours spend in front of the Excel spreadsheets, and with no guarantee of success. With BigTime’s demand planning software, this changes now.

BigTime offers an innovative, AI-powered approach to demand planning and forecasting. With this tool, you will be able to:

- Oversee the information on resources, funds and plans for all the projects – both current and past.

- Analyze data on tasks, expenses and project execution – we’ll turn it into intuitive reports ready in seconds.

- See operations planned by other managers in your company and monitor any changes their make live, whenever they make a change to rates, allocations or overheads.

- Create draft projects to simulate different scenarios and choose the best path to success every time.

The results? Saved time, improved utilization rates and higher profitability. For example, Future Mind saved over 3.500 hours of billable time using their improved resource management, while Draper and Associates improved their productivity by over 66%.

That’s not all we have to offer, though. With BigTime, you also get access to skill and resource management, project management, invoicing and intuitive payments, and more. And, if that’s still not enough for you, we can also help you combine the tools you know and trust with BigTime thanks to seamless integrations.

Sounds good? It looks even better – book a demo with BigTime right now to see how we can help you transform your data into accurate forecasts.